“

Discover the ultimate precision and versatility with the Xtool Laser Engraver Hawk F1 IR+DIODE, a cutting-edge laser engraving machine designed to meet the demands of both hobbyists and professionals. Whether you’re creating laser engraved Yeti tumblers, customizing laser engraved products, or working with laser engravers for metal, this machine delivers unmatched performance and reliability.

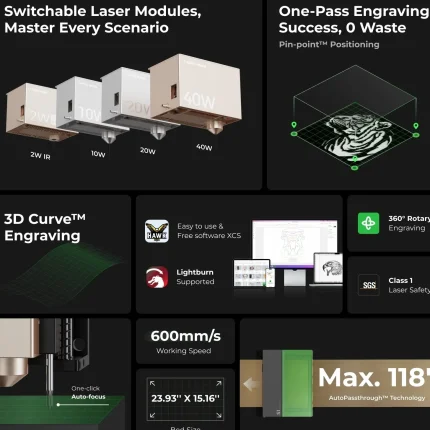

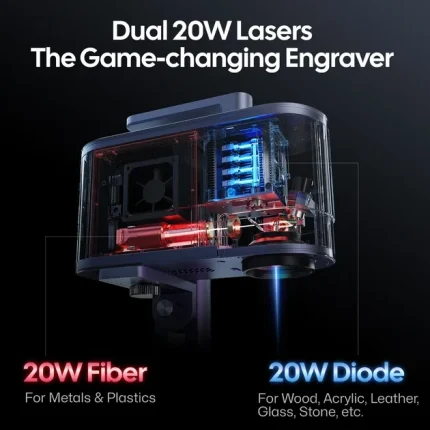

The Hawk F1 IR+DIODE combines dual-laser technology, featuring both IR and Diode lasers, to handle a wide range of materials with ease. From wood and leather to metal and glass, this machine ensures crisp, detailed engravings every time. Its advanced safety features and user-friendly interface make it accessible for beginners while offering the precision required by experts.

- Dual-Laser Technology: Equipped with both IR and Diode lasers, the Hawk F1 can engrave on a variety of materials, including metals, plastics, and organic surfaces.

- High Precision: Achieve intricate designs and fine details, perfect for creating personalized laser engraved products like jewelry, phone cases, and more.

- Versatile Applications: Ideal for crafting laser engraved Yeti tumblers, custom signage, industrial marking, and more.

- Safety First: Built-in safety mechanisms, including an emergency stop button and protective eyewear, ensure a secure working environment.

- User-Friendly Design: Intuitive software and a compact design make setup and operation seamless, even for beginners.

Whether you’re a small business owner looking to expand your product line or a DIY enthusiast exploring creative possibilities, the Xtool Laser Engraver Hawk F1 IR+DIODE is your go-to solution for high-quality, professional-grade engraving. Transform your ideas into reality with this powerful and versatile machine.

More you like:

Laser engraver machine✓Laser for engraving machine✓Laser cutter and engraver✓LaserHawk LH4 | Wood laser cutter✓Best laser engravers for home✓Laser engrave LaserHawk LX1 Series | Laser cutter and engraver ✔Laser engraver for metal ✔Hawk S1 Enclosed Diode Laser Cutter | Laser engraving machine✓Laser cutter and engraver✓Laser engravers✓Diode Laser Engraver✓Laserhawk LH5 | Laser engraving machine✓Laser cutter and engraver✓Laser engravers✓Diode Laser Engraver✓Laserhawk LH5 | Laser engraver machine✓ Fiber laser engraver✓Laser engraver for metal✓LaserHawk LH3 | Laser engraving✓Laser cutter machine✓Laser engraver engraving machine✓LaserHawk LH2 | Laser engraver machine✓Laser for engraving machine✓Laser cutter and engraver✓LaserHawk LH4 | Laser engraver machine✓Laser for engraving machine✓Laser cutter and engraver✓LaserHawk LH4 | Wood laser cutter✓Best laser engravers for home✓Laser engrave LaserHawk LX1 Series

Luis Wright (verified owner) –

**Specific Project Experience:**

– **Architectural Models:** Utilized the laser engraver for intricate detailing on architectural models using acrylic and wood. The machine excelled at creating precise lines and textures, enhancing model realism.

– **Material Behavior:** Acrylic required careful power adjustment to avoid charring, while wood benefited from lower speeds for cleaner cuts. Encountered warping in thin materials due to heat; solved by pre-drilling holes and reducing laser intensity.

**Technical Performance:**

– **Power & Precision:** Consistent engraving at 30W for acrylic and 45W for wood, achieving sharp details without burn marks.

– **Software Experience:** Used Adobe Illustrator with a RIP driver for vector files. Software learning curve was minimal, ensuring quick setup.

– **Special Features:** Leveraged variable speed control for smooth curves and air assist for dust management during engravings.

**Business/Creative Impact:**

– **Workflow Improvement:** Reduced production time by 40% compared to manual methods, enabling faster project turnaround.

– **Customer Feedback:** Clients praised the precision and quality of the models, leading to increased repeat business.

– **ROI:** Machine paid for itself within a year through saved materials and labor costs.

**Comparison & Value:**

– **Previous Tools:** Outperformed CNC routers in speed and detail. Laser engraver was faster with cleaner edges.

– **Cost-Effectiveness:** Lower material waste and minimal maintenance costs improved profitability.

– **Time Savings:** Reduced setup and production times by 30%, boosting efficiency.

Jin Weber –

“Exceptional laser engraver! Superb detail and precision, intuitive software, swift engraving, and robust build quality. Highly reliable and a true workhorse. 🌟🌟🌟🌟🌟”